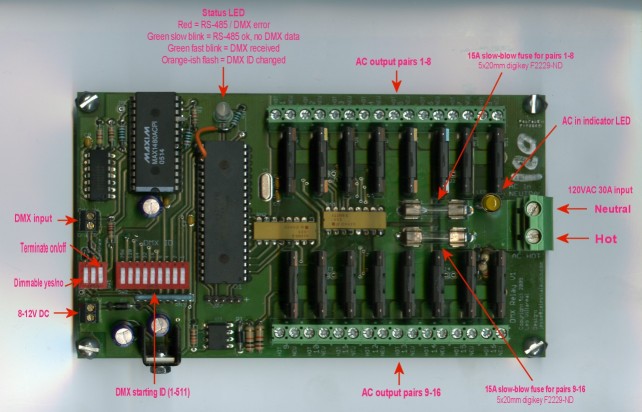

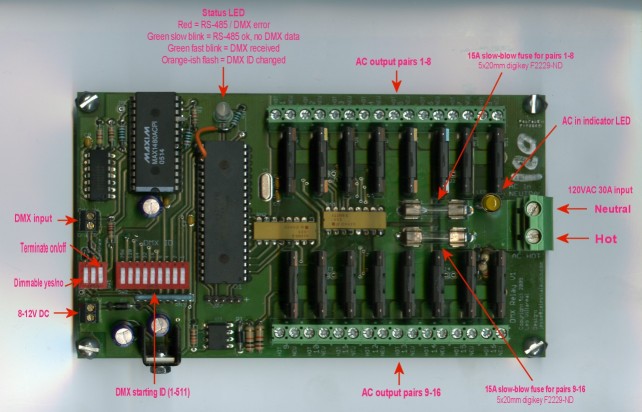

16 channel DMX controlled 3500W AC light switcher

This web page documents a DMX-controlled lighting board.

Board is 6.25 x 3.75 two-layer

Project timeframe: July 2005

Client: Leo Villareal

Initial webpage creation: July 8 2005

Minor edits July 15 2005

Top view:

Larger Image

Feature set:

- Fully isolated RS-485 input (MAX1480)

- DMX ID settable 1-511 via DIP switch, changes are immediate (no

power-cycle needed), status LED blinks orange to show change detected

- RS-485 termination on/off via DIP switch

- AC dimmable yes/no via DIP switch (to protect non-dimmable lights

or other equipment from damage)

- Dimming synchronized to AC zero-crossing

- AC triacs isolated

- 240W per channel as built for cost savings, up to 1000W/channel

possible. No snubber circuitry for cost savings, but snubbers for

each channel possible

- Single 30A AC input

- Dual 15A fuse protection

- AC power-is-on indicator/warning LED

- Status LED indicates RS-485 / DMX error (red), good but no data

(green slow blink), and DMX frames incoming (green fast blink)

- 8-12V DC @ 300mA, reverse polarity protected

Significant parts:

Maxim MAX1480ACPI, fully-isolated RS-485 transceiver

Microchip PIC18F442

6N138 optoisolator (for AC zero-cross detect)

Sharp S102T01 solid-state relay, 2A rating (higher ratings available)

Phoenix Contact 1714971 2-position 30A terminal block

Phoenix Contact 1935307 16-position 16A terminal block

All parts except for the Maxim IC are available at digikey.

Background

My client has an 80-channel board from years ago that plays fixed

patterns (no DMX or any other inputs) for an art piece that has now

been sold. In order to make the piece more modular and flexible

in terms of control options and installation (the 80-channel board is

one huge pcb), I was tasked

with designing something with the same solid-state relays (they have

worked great) and new everything else. In addition, the ability

to control high-power lighting - several high power lights as well as

16 lower-power ones that add up to a lot - was desired.

Technical discussion

AC power design was something new for me, and it was exciting to figure

out the practical aspects of designing for it. To start off with,

you have to get power in! There are limits to what terminal

blocks of reasonable size can handle, and I spent awhile digging

around. The 30A one I used is sensibly sized and is around the

limit of what is normally available as AC feeds. While higher

current blocks are available, they are much larger and are overkill for

the situations this board is designed for.

Fuses. Fuse the AC hot side, not the neutral, so if the fuse

blows, the hot is disconnected. Of course, without a polarized or

3-prong plug there is no way to ensure the AC is wired correctly.

As it turns out, 30A fuses are relatively scarce, so this design splits

the 16 outputs into two banks of 8 with individual 15A fuses.

This is better for a number of reasons: pcb traces can be reasonably

sized, connections to normal 15A or 20A circuits are protected (vs.

with a single 30A fuse), and current limits on the 8-pair terminal

blocks are respected.

pcb trace width - turns out you need a fairly wide trace to keep the

board from getting toasty. This was a useful tool for me:

Trace

Width Calculator

and I used 2oz copper, which pcbfabexpress.com (my favorite prototype

place) uses for their boards.

RS-485 isolation. Isolation is desirable in situations where you

can't control how an installation is wired. If having a common

ground between all RS-485 devices is possible and there aren't power

lines running parallel to the signal pair, it probably won't be

necessary. In this case these boards will be used in situations

where the RS-485 comes from something powered by one generator and the

AC for the lighting from another, installed and run by people who don't

do it for a living (and very well may not be sober at the time!) the

more robust, the better. The Maxim IC is pricey at $16 each (vs.

$1 for a standard RS-485 transceiver) but it does it all.

Zero-cross detection. To do good dimming, it has to be

synchronized with the zero-crossing of the AC line, since once turned

on, triacs stay on until the AC voltage goes to zero. So the

strategy is to time when you turn them on (briefly) such that you get a

fraction of the remaining AC cycle, and you know how much of the cycle

they are on for. Important disclaimer: dimming has not been implemented in

software yet in this design, so there may be subtleties to this

that have not been reached. The hardware detection works

great, and is based on the elegant zero-cross design in the circuit

below (lower left corner, the 6N138). Important: R22 & R23,

the 10K resistors on the AC line, must be 1/2W. MIDI dimmer

w/zero-cross (pdf schematic)

DMX receive software. The DMX specification is on numerous

websites (like here)

so I won't discuss it. Generating DMX is cake, but receiving DMX

with a

microcontroller can be a little tricky. One simple way is to send

the signal to both the UART and another pin to trigger an interrupt,

and use timers to count how long the signal has been high or low or

whatever so the detection of the DMX break and mark-after-break doesn't

involve the UART. Unfortunately in this design there were

absolutely no extra pins on this PIC, so it had to be done with the

UART alone. I found some code on the user forum for CCS, the

used-to-be horrendous but finally relatively bug-free C compiler I

unfortunately use. (CCS

forums) There is no way to link to the post, but searching

for DMX will yield some results. I completely rewrote it for my

needs but followed his strategy and it works fine. In essence

framing errors are used to determine DMX start of frame, and a framing

error with received data of zero indicates the frame started, and if

the next byte is received without error and is a zero it is the start

code.

The entire design is through hole, another request from my client, so

that it can be soldered together by "normal humans" and not require

machinery or me with the fine-tip soldering iron and magnifying

glass. As it turned out, most of the design had to be through

hole anyway - terminal blocks, fuses, solid-state relays, Maxim chip-

so

this didn't add much to the board real estate, and simplifies contract

assembly as well, it can just be run through the solder wave.

However,

this precluded using a higher pin count PIC, which would have

simplified DMX receive software (see previous paragraph)

and opened the door to more DIP switch options.

Mistakes, tools and future work

All in all pretty good, pcb changes for the prototypes were minor and

are easily fixed for the next run of boards. The two errors that

were made:

- polarity of the driver enable pin on the MAX1480 was wrong.

DE (called DE' as well) is active-high or active-low depending on if

the datasheet is talking about the pin itself (page 10) or the resistor

driving it (page 12). Confusing. Page 16 has a truth table

that spells it out - the resistor R2 (page 12) is needed even if it

will never be used as a transmitter and is tied to ground to disable

the transmitter.

- I assumed it would be possible to configure the PIC so that the

UART transmit pin could be used as a general-purpose i/o while the

receive pin goes to the UART - nope. If the UART is enabled, both

pins are for the UART. Kinda dumb and an unfortunate restriction

- other microcontrollers don't require this, and it wastes a (valuable

in this design) pin. So I had to do board patch and deal with

receiving DMX with just the UART - see above.

Future work - dimming is not implemented! As soon as my client

needs dimming capability it will be added. In order to work

outside of the US, it will support both 50hz and 60hz,

auto-detect. Operation at 240VAC would be great, however the

Sharp solid-state

relays are only rated for 125V (not sure if a 240V version is

available) and the resistors that current-limit the zero-cross

optoisolator and the AC-is-on LED have to be 20K, not 10K. Not

sure if the terminal blocks are rated for 240VAC either.

Tools used: Eagle 4.14 (latest of this writing), which

I wholeheartedly recommend, and the CCS PCH C compiler, which was

horrendously buggy for 18 months and is now more or less reasonable.

Schematics? Board layouts?

Gerbers? BOM? Software downloads? ...

Sorry, this was a paying client project and the IP is not available for

give-away. If you would like to purchase some boards or have a

proposal for commercialization of the design, feel free to contact me.

Home